Small Scale Brewing

The small scale brewing method is the method in which “craft beer” brewers brew their product. This method is also called the batch method and takes a longer time to finish than the large scale or “continuous” method. The method creates batches of beer which sit in large fermenting and maturing kettles for long periods of time, in which time they ferment all the sugar into alcohol and settle into the final product.

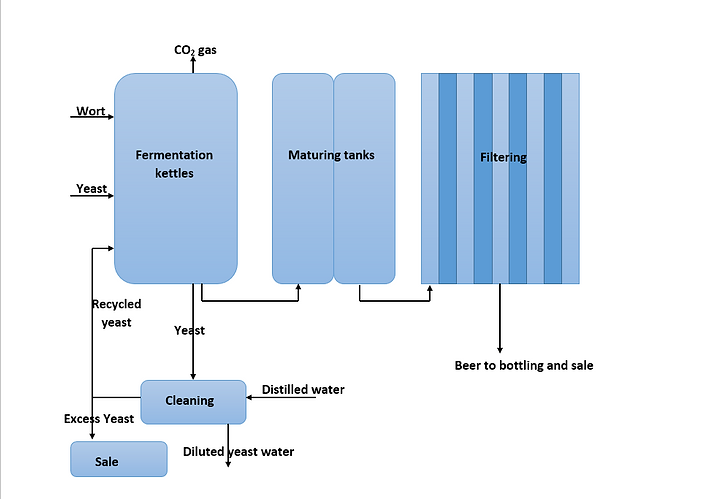

The long production time means that with each batch a range of equipment cannot be used to make any more batches until the last one is finished and cleaned out, making it substantially more expensive to run on a large scale. Once the batch has finished fermenting the yeast is extracted from the tank by pouring off the section of beer where the yeast has settled in, which is then filtered and the yeast cleaned, ready for reuse or sale. The beer is then drained from the kettles and pumped into maturing tanks which turn the “green beer” into something closer to the final product. Hops will be added at this stage to flavour the beer in exactly the way that the brewer wants. After being sufficiently matured for the required product the beer is then pumped through the filtering system, which removes any hops, yeast, or other unwanted pieces, making the beer clear and ready to be packaged for sale.

Hops are added at different stages during the wort boil, and adds different flavours and aromas to the mix. Bittering hops are added earlier in the boil so that the alpha cids have enough time to isomerise which create the distinct bitter flavours that hops are known for. Aroma hops are added later on in the process and contribute a greater amount of beta acids to the beer, giving the beer its aroma. This variablity in timing allows the flavours to be tailored very easily by the brewers as they can add them at different times to influence different flavours.

The fermentation process needs to be kept at a steady temperature from around 10 degrees centigrade, if using a bottom breeding yeast (Beer brewing process. 2008) or if using a top breeding yeast the process needs to be kept between 15 and 20 degrees. This keeps the yeast at a temperature that allows it to breed well and to convert the sugars from the wort into alcohols most effitiently. The fermentationtanks are designed to allow easy and energy effitient temperature control between these ranges, and in some factories they keep the entire factory at this temperature to minimize equipment costs. Once the beer has finished fermenting to the standard of the brewer the beer is moved to a seperate tank, before being cooled to almost freezing. This encourages the yeast to settle to the bottom of the tank and causes unwanted flavours to become insoluble in the beer. This process makes the beer have a smoother taste which is desirable to consumers.

Filtering takes the conditioned beer and removes the yeast, insolubles, and dregs. This makes the beer have a polish and gives it a brilliance which certain forms of bee require. This process can be done using industrial pad filters or in some factories diatomaceous earth is used, being packed fine enough to filter out the required bits but not packed tight enough to slow down the passage of the beer through the filter.

The beer is then bottled or kegged, packed, and transported to the consumers and points of sale.