Project Charter

This project charter is for 141.112 – Food Technology 2: Creative Solutions,

coordinated by Alistair Carr.

Project Authorisation

Team Supervisors:

Richard Love

Alistair Carr

Overview

Beer has been a large part of New Zealand culture since the introduction of the beverage to our country in 1773 by Captain James Cook. During the 19th and 20th centuries, beer became the most popular alcoholic beverage, and continues to hold this position today, accounting for 63% of alcohol available in New Zealand today (The Beer Academy, 2015).

Context

In New Zealand’s beer industry today, over 285.5 million litres of beer is available for consumption annually. New Zealand is home to over 25 professional breweries which supply our country’s large demand for this alcoholic beverage, supplemented by international imports (Statistics New Zealand, 2013).

Due to the large scale of manufacturing of beer in New Zealand, a lot of waste product is generated from production. The waste created from brewing beer is generally high in moisture content and large in bulk, making the brewing industry a high contributor to overall organic waste. The majority of the waste created from brewing beer is either in the form of water or spent grains (Thomas & Rahman, 2006).

Although most waste is usually used as fertiliser, compost and feed due to the established connection between the beer industry and the agricultural industry, there is still a large portion of the waste that is not further utilised or recycled, which is currently dumped in landfills. This has environment consequences that we aim to minimise during this project. With the current emphasis on sustainability and environmental protection, the waste generated from brewing beer raises concerns for the future of the industry.

Beer is currently brewed using either a small or large scale process. The process used depends on the size of the brewery and their outputs. In both processes there is room for development of technology to improve the efficiency and sustainability of brewing. By creating a solution that advances the brewing process, cost of production can be decreased which will in turn increase revenue for producers in the beer industry.

There is a worldwide trend of decreasing beer consumption, which is aided by the laws and legislations implemented by the government. This drives a shift away from higher alcohol beers and decreases the international demand for beer. Therefore new ways to increase the demand for beer both in New Zealand and overseas are needed to increase the New Zealand beer industry.

By addressing these issues and developing solutions to minimise environmental damage, improve efficiency, and increase the overall demand for beer, we can help to secure the beer industry looking forward to 2025.

Key Stakeholders

The main internal key stakeholders in this project are the members of the brewing industry in New Zealand. This ranges from suppliers of the inputs, brewers, the importers and exporters, and the customers. Consumers in the export market are also stakeholders in this project.

In this project, the main stakeholders we will be focussing on are the brewers, as they are the ones generating and disposing of the waste their production creates. Should we be able to create a solution minimise or process the waste products of, not only will the brewers benefit, but the wider community due to reduced environmental concerns. Improving efficiency of the brewing process will also affect the brewers directly.

Another main stakeholder is the consumers, both in New Zealand and in the export market. The solution must be accepted by consumers in order to achieve the goal of future proofing the beer industry.

The main external stakeholders in this project are the Engineering Department and Massey University. Massey University is our client for this project, and they are who we will be presenting our deliverables to.

Project Outcomes

A successful outcome would be to generate ideas to secure the future of the beer industry in New Zealand, potentially expanding it further. The success of our project can also be defined by our recommended solution reducing the environmental impacts, and improve efficiency of beer production in New Zealand. From a social perspective, our solution would aim to reduce consumer’s concerns about the effects of production and waste, and increase overall demand. A secure industry 10 years in the future will protect stakeholders financially, and the possibility of growth within the sector will offer financial benefits.

Project Constraints

There are a number of constraints associated with this project. Below is a list of possible constraints we may have to work around:

-

Health and safety regulations

-

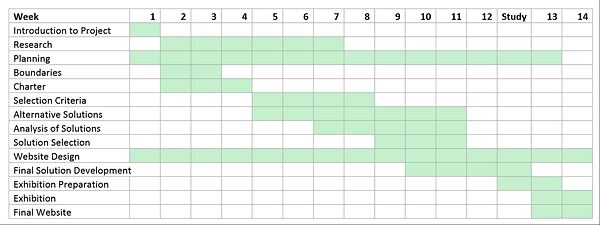

Time constraints

-

Transportation

-

Profitability

-

Storage

Project Scope

For the purpose of this project, we are not only concerned with the ‘on-site’ process of producing beer, but also the inputs for beer, the waste produced, and the packaging of the beer.

Project Risks

There are many risks that pose a threat to the success of our project. These risks may develop over time, and others risks may arise throughout the duration of the project.

-

Data and information: There are risks associated with the data and information we collect throughout this project. These risks may be loss of information due to computer failure and not having relevant data and information available or accessible. We will be able to minimise these risks by regularly backing up our information, and storing the information in multiple places.

-

Illness or incomplete work: A risk in this project is incomplete work due to potential illness or grievance of an individual. To help minimise this risk, we will spread the workload between team members equally, and ensure deadlines are achievable for all members.

-

Unachievable solution: Developing an unachievable solution is a risk for this project. As we are predicting the industry in the future, the solution we develop may not be applicable or achievable in 2025.

Project Management

Resources Available:

-

Team members (150 hours each, 600 hours in total.)

-

Project supervisors (experience, knowledge and guidance)

-

Massey University Library and Website

-

Massey University Micro Brewery

-

Other internet and library sources

Deliverables

At the end of our project, our client, Massey University, should be supplied with a website and presentation containing our research information, future prospects and solutions and weekly updates outlining the progress of our project.

Change Control

Any potential changes to the project plan or charter will be discussed thoroughly as a team to decide if this is the best course of action. Should further guidance on potential changes be necessary, we will address these with our project supervisors.

Health and Safety

As we are dealing with a food/beverage industry, health and safety is paramount during our project. Any experiments and investigations will be supervised, and appropriate health and safety precautions will be put in place when necessary.

Communication Plan

Our project team will meet at least once a week on Mondays during our project day. Further meetings will be scheduled throughout the week should additional meetings be required. We will also meet with our project supervisors weekly to keep them updated with our process. Weekly updates will be written to ensure our team stays on track and makes necessary adjustments in order to meet deadlines. We have set up a Google Drive and a Facebook page to share information and keep in regular contact.